SERVICES

Commissioning

Insulation Resistance Test

By applying a voltage to the dielectric barrier and measuring to specifications, this test verifies insulation integrity and proper installation.

Winding Resistance Test

This type of test ensures correct connections and verification of no serious misalignments or open connections.

Transformer Turns Ratio Test

This test measures the turns ratio of the transformer in the primary and secondary coils. It also verifies that the actual voltage matches the specified voltage ratio of the initial design.

Visual Inspections

Visual inspections as part of your predictive maintenance program check for cleanliness, cracked insulators and bushings, paint condition, oil levels, oil leaks, and grounding state.

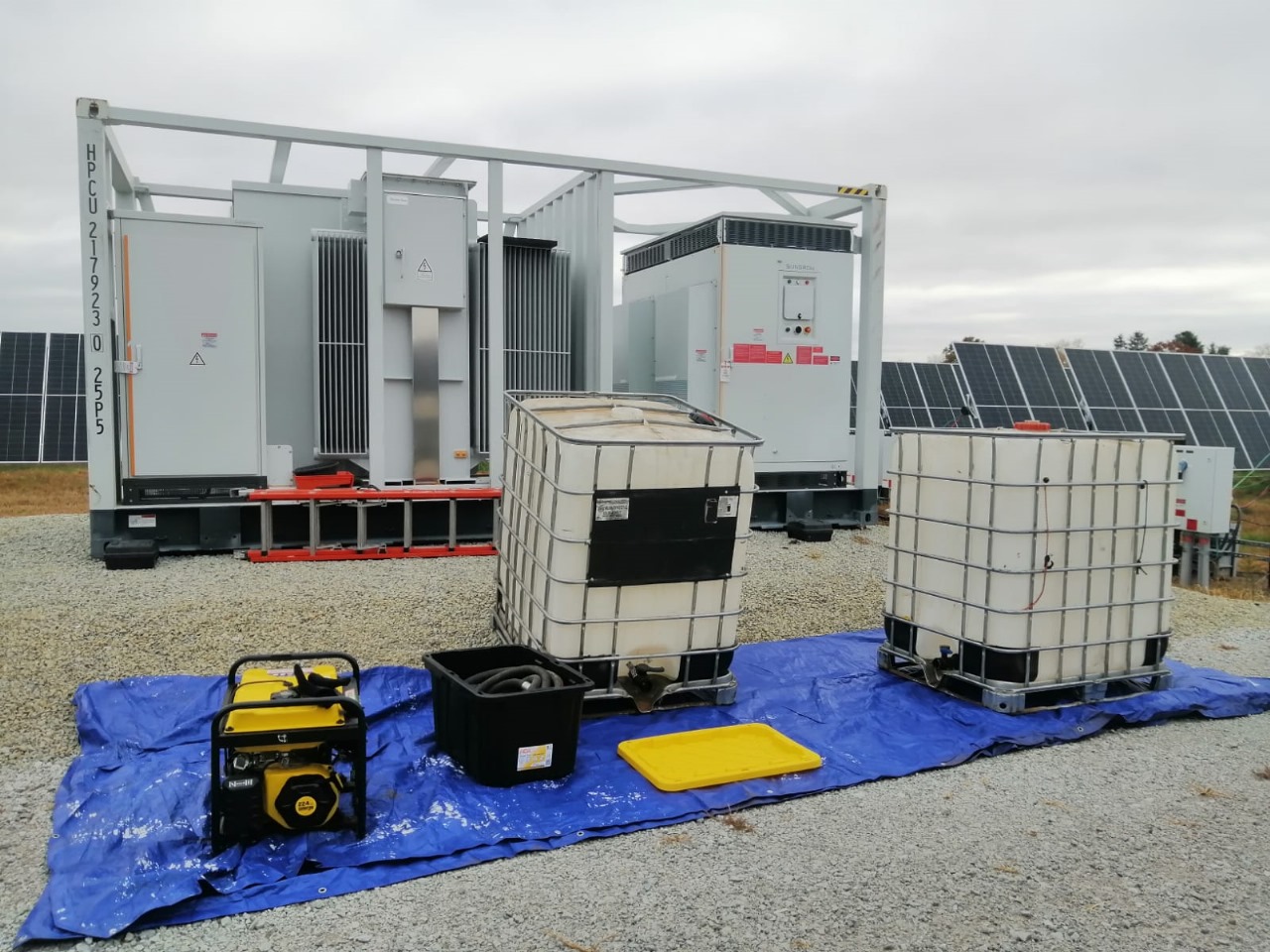

Treatment / Oils

Advanced mobile oil processing equipment provides vacuum, filtration, degassing, and dehydration of fluids/oils to restore dielectric strength and insulation characteristics.

Oil Analysis

Proper oil analysis is critical to determining the operating efficiency of a transformer, preventing sludge formation, and maintaining cooling capacity.

Maintenance

Proactive Maintenance

Electric power is the key element of your business. We understand that it is essential to your operations, however, it can also be dangerous and expensive. Although large power transformers are among the most reliable pieces of equipment used in electrical power systems, failures do happen. The need to replace a transformer means financial and productivity losses. In many cases, a transformer can be saved if the problem is anticipated and detected before it becomes serious.

Benefits of Proactive Maintenance

Routine inspection and scheduled maintenance will eliminate unplanned downtime and improve your bottom line while maintaining uninterrupted power generation. Ensuring the continued reliability of electrical distribution systems. Minimize emergency repairs. Ensure optimal system performance, efficiency, and security.

Preventive Maintenance

The continued efficiency of electrical systems requires proper analysis, interpretation, and service recommendations. Cousus' experienced field technicians provide complete preventative maintenance testing services to ensure reliable operation of new and existing transformers and will also compare the results to baseline measurements to determine the overall health of the transformer.

Vacuum Processing and Oil Degassing

These services remove water, gases, and mechanical impurities to maintain the strength of the dielectric oil and the insulation system.

Water-in-Oil Analysis and Dissolved Gas Analysis (DGA)

These tests are used to identify the essential properties of transformer oils and provide a more accurate assessment of their condition.

Dissolved Gas Analysis

Dissolved Gas Analysis.

Dissolved Water in Oil Analysis

Dissolved Water in Oil Analysis.

Occupational Safety and Health Administration Compliance

Emergency Service

To help you deal with emergency situations. Cousus Green Energy is available 24/7 for critical emergency needs, including:

Testing & Maintenance Equipment

Transformer Leak Repair

Transformer Gasket Replacement

Spill Clean-up/Recovery

Failure Analysis

Spill Clean-up/Recovery

CPC 100 + TD12/15

RAYTECH MiniAtos

RAYTECH WR14 Raytech Winding Resistance Meter

RAYTECH TR-MARK III 250V Turns Ratio Meter

MEGGER S1-1068 - 10kV Insultation Resistance Tester

Megger S1-568 - 5KV Insulation Resistance Tester

WILSON Hydraulic Filtration System